If you intend to build a motion simulation platform, you’re in the right place. The cost-effective AASD servo motors are currently the most efficient solution for this purpose. The Motion4Sim controller has been precisely developed to utilize these motors to their full potential.

All other motor drivers that support Step/Dir operation can also be connected and controlled. For example, Nema 17, 23, 34 with digital stepper motor drivers or other servo motors such as YMPC AASD, Delta B2, Lichuan LCDA4 can be utilized.

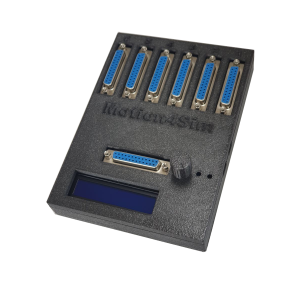

The M4S-AASD15A servo controller enables fast and seamless transmission of motion information from the PC simulation to the servo motor. The data exchange occurs between interface programs such as Simtools, FlyPT Mover, Motion4Sim Dashboard.

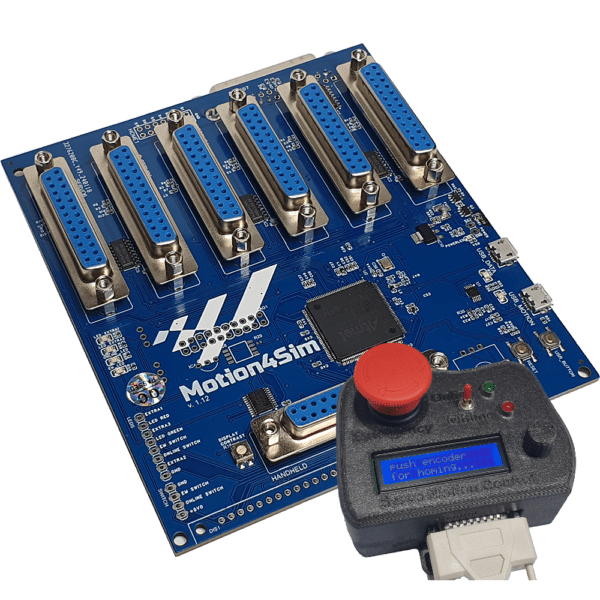

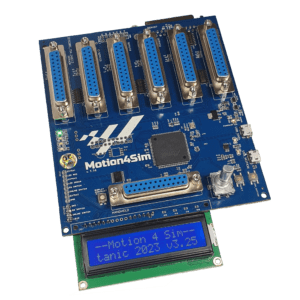

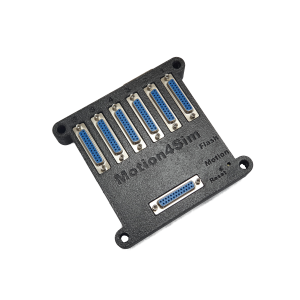

The interface software calculates the motion vectors and transmits the values via the USB interface to the M4S servo controller. The controller then controls the servo motors and also provides the ability to calculate and smooth motion cues. The servo motor amplifiers are connected with DB25 cables.The pins of the connectors match the pinout of the AASD servo.

function and technical properties of the controller supported:

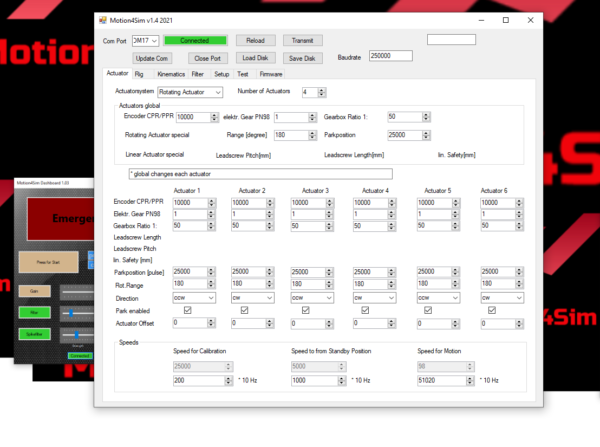

- Control of 7 servo motors

- Pulse speed up to 550 kHz

- Step/Dir mode

- Actuators are fully configurable, including parameters such as inline, foldback, direction, pitch of a leadscrew, gearbox resolution, unlimited stroke length, encoder resolution, etc.

- Freely adjustable parking position, so also allowing for horizontal and vertical parking in 6DOF configurations.

- Query and evaluation of torque signal for homing as well as error status

- All types of actuators are supported, linear, rotating, or 360° infinitely rotating.

- automatic home calibration on power up or re-connection with or without limit switches (torque controlled)

- Display of parameters via 16×2 LCD display, full menu system

- LEDs for status indication

- E-stop, Force Offline buttons, and switches

- Operation via rotary encoder with push button

- Emergency stop switch for servo functions

- support for servo motor brakes logic

- Serial USB connection for data transfer with crc checks for data safety

- 32-bit processor to calcualte motion cueing platform position in real time (500 hz)

- internal motion processing running at 1000hz

- Full inverse kinematics calculation for all common 2, 3, 4, 5, 6 DOF rigs in realtime (500hz)

- Storage of settings in internal memory

- position control of actuator limits

- platform health check to ensure all actuators are active during gaming

- park function no rig is dropping when shutoff power

- support of diy belt tensioner system with autohoming and live adjusting srength

- Soft start with morping algorithm to prevent jerking or jumps from occurring

- internal pulse filtersystem for smooth motion cues

- built-in intelligent fully adjustable spike filter to protect both life and machine.

- Service mode and test function for the actuators for maintenance and control.

- usb powered with 5V

if you are not sure about support of your project feel free to contact us.